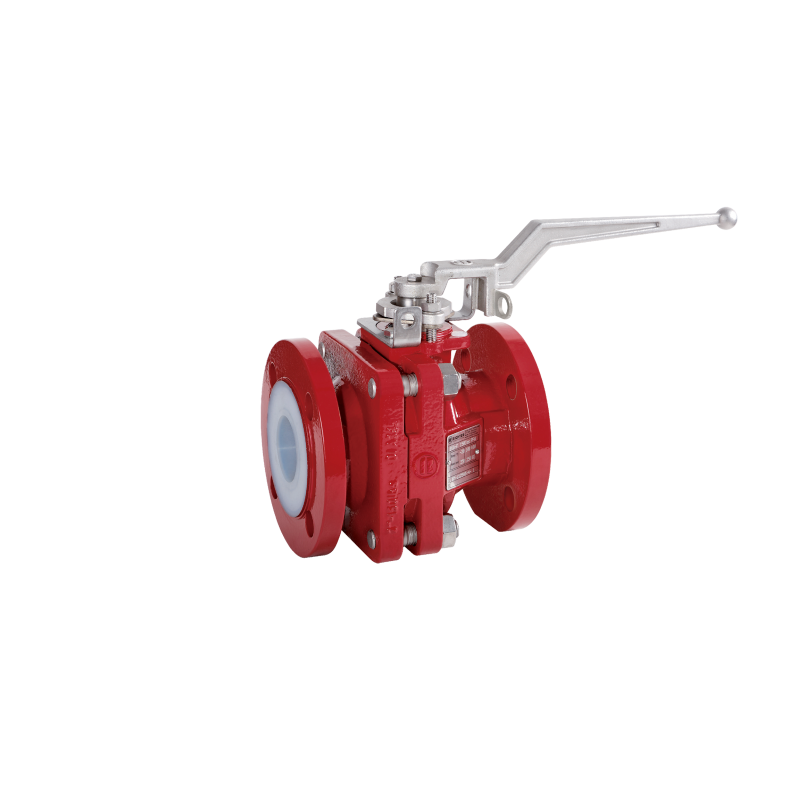

The design of the ball valves series BVA is based on more than 30 years of application experience with lined ball valves. They provide an excellent ratio of economic and operational performance in a wide variety of process applications. The Richter ball valves are designed

Heavy-duty ball valves with ENVIPACK stem sealing

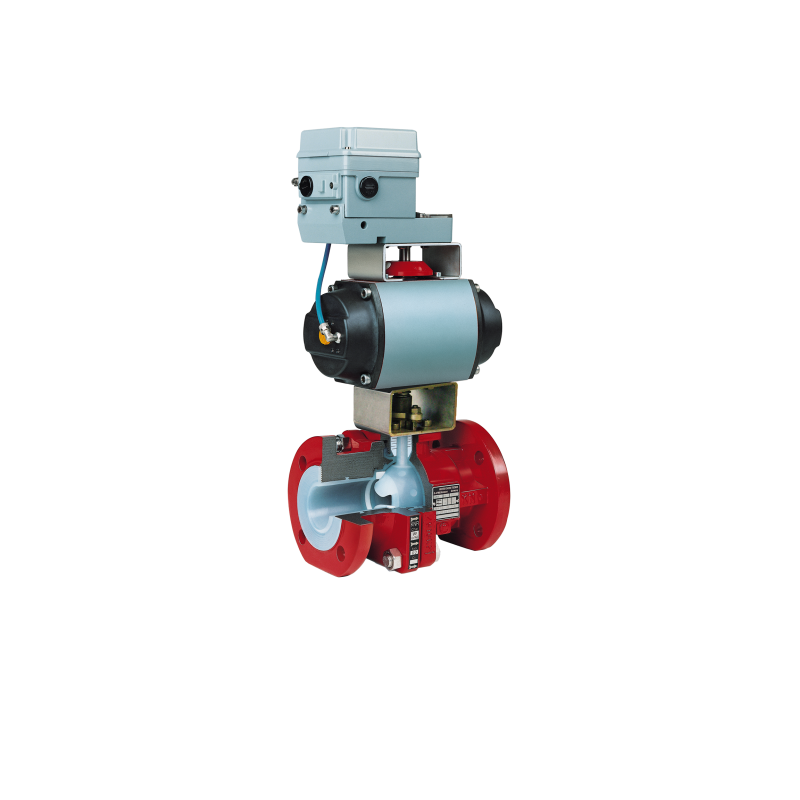

The ball valve family, KN, excels by offering problem solutions from a modular system. The selection of fluoroplastic linings (i.e. PFA), the large temperature/pressure range and the numerous options permit a tailormade solution for virtually every application involving highly corrosive and ultrapure media – with more or less the same components!

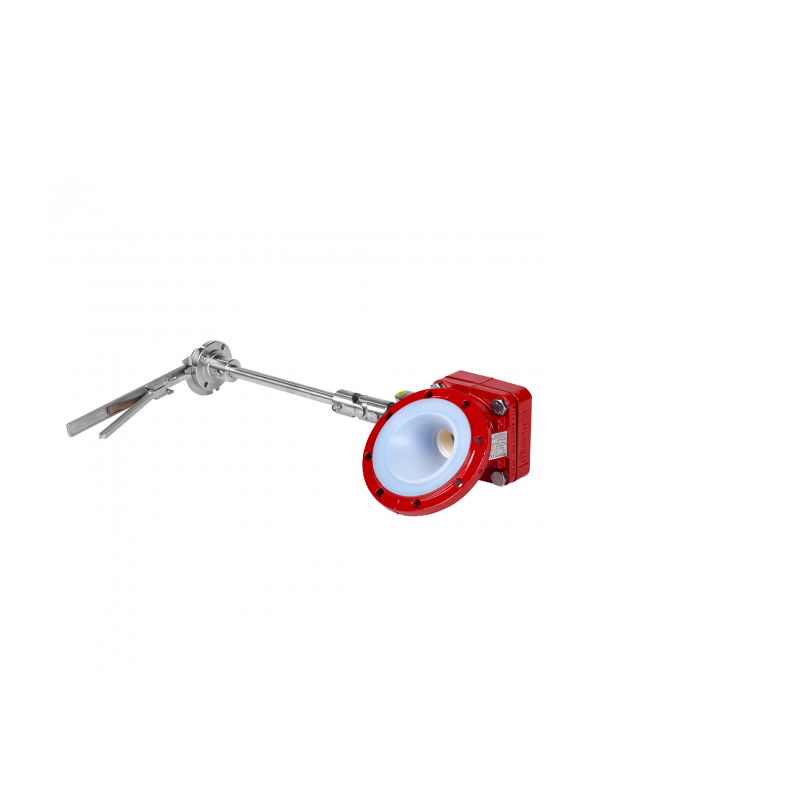

Built on Richter’s PFA lined NK series, the NKS-T/F Butterfly Valve is designed to fit with the TE/F Bottom Valve, it can, however, also be used on top of the tank container. The sandwich-type body is equipped with PTFE and the disc is lined with PFA for maximum corrosion resistance. The single-piece disc/stem is maintenance free and the self-adjusting top and bottom stem sealing warrants reliability, even with many switching cycles.

Richter wafer-style and lug-style butterfly valves Fields of application Richter butterfly valves have proved successful in a wide variety of process plants. • Shut-off, throttling and control of corrosive, hazardous and pure liquids, gases and vapours, e.g. – wet Cl2 gas and NaOH in chloralkali electrolysis – large flows in the distribution and treatment of H2 SO4, HCl, NaOH, NaOCl, chemical effluent etc. • FDA-compliant, wetted materials for use in food processing, pharmacy and similar fields. • Also suitable for free-flowing, low-abrasive bulk materials in the version with a metallic disc/stem unit. • The compact butterfly valves are advantageous in confined spaces – e.g. under vessels. • Butterfly valves are economical valves: easy to install and dismantle, attractively priced, and compact.

Safety in corrosive and high-purity applications,

Only one certification for vapours, gases and liquids. Your advantages: increased flexibility, no mix-ups of single components, reduced storage requirement

Flow control of corrosive, hazardous, pure and/or slightly solids-laden liquids, vapours and gases in the chemical, pharmaceutical and other industries. The Richter RSS series is especially suitable • for media where stainless steel is not sufficiently corrosion-resistant. • as an alternative to valves made of special metals (Hastelloy®, Monel®, titanium etc.). • for environmentally critical media (German Clean Air Act – “TA-Luft”). • for metal-reactive media, e.g. H2O2. • for biotechnology and high-purity media where good cleaning and anti-adhesive surfaces are important. • for highly permeating media.