SPC is a leading provider of pump and compressors, offering a wide range of products to meet the diverse needs of various industries.

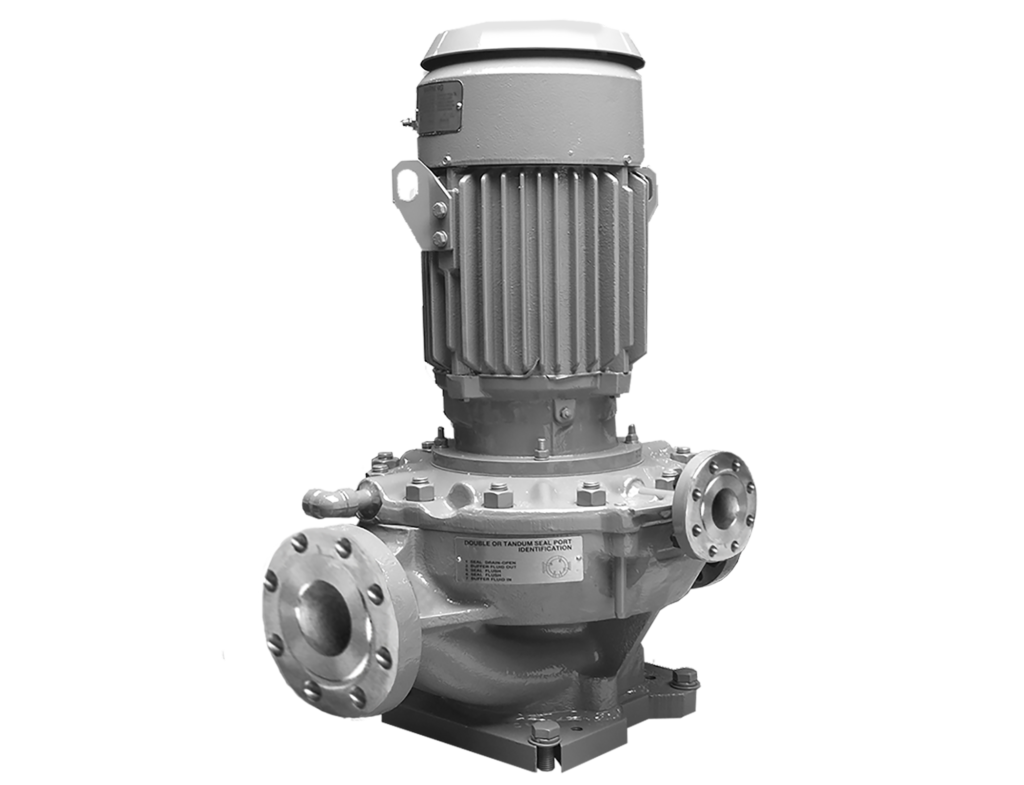

API 610, OH3 and OH5 direct drive reliable space saving process pumps for hydrocarbon and chemical processing, upstream and midstream Industries.

Multi-Stage Pump Performance in a Compact Single-Stage Design

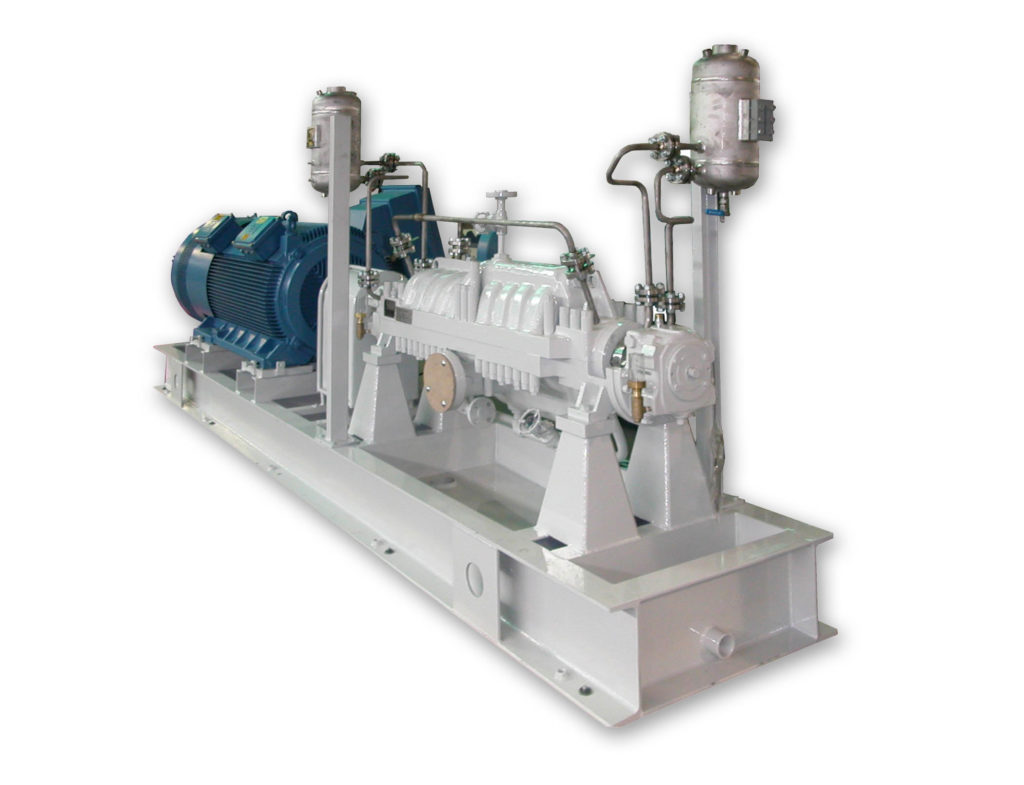

API 610 heavy duty integrally geared driven pumps are engineered for critical extremely high-head services required for processing fertilizer, PTA and urea.

Industrial grade Sunflo pumps are specifically designed for High Pressure applications such as boiler feed, NOx suppression, reverse osmosis, or high pressure wash down applications that are common to power generation, maritime, transportation or food & beverage industries.

ANSIMAG sealless magnetic drive pumps are more energy-efficient than mechanically sealed pumps. An innovative rear casing generates no eddy currents thus eliminating heat generation and reducing energy costs. Because ANSIMAG pumps do not have seals – there are no leaks, no emissions and no costs related to seal maintenance.

An HMD Kontro sealless pump is a conventional centrifugal pump without mechanical seals. Using modern engineering and technologies developed over decades of experience in the handling of harsh and hazardous fluid

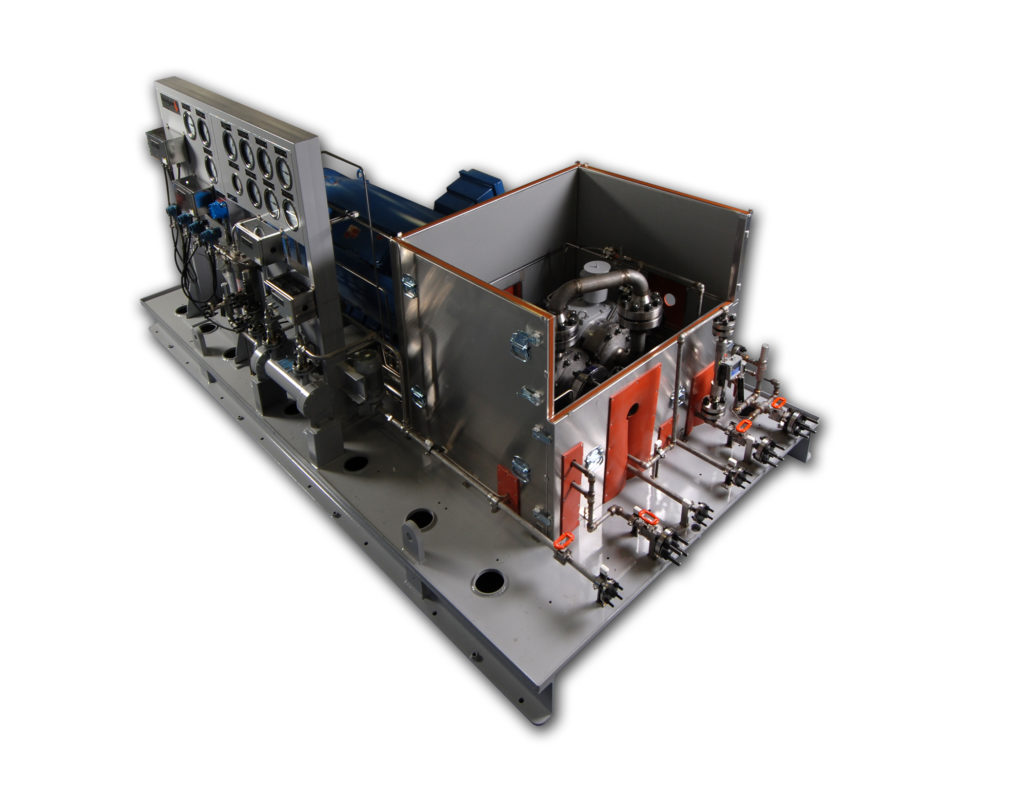

Today, the Sundyne compressor line features single- and multi-stage centrifugal designs for API 617 and fit-for-purpose applications including fuel gas boost in power generation. Each model is custom built to provide pulsation- and vibration-free operation, and to deliver oil-free process gas with zero emissions.

Sundyne’s PPI diaphragm compressors deliver non-contaminating gas compression, through a leak-tight mechanism with static seals that do not need to be purged or vented. A set of metallic diaphragms isolates the process media from the piston & piston rings to completely eliminate the risk of cross contamination. Sundyne’s PPI compressors present zero leakage threat to the atmosphere, providing an ideal solution for safely handling ultra-pure, corrosive and volatile gases.

Process engineers utilize Marelli heavy duty pumps for refining, petrochemical, offshore, floating production storage and offloading (FPSO) operations, floating liquified natural gas (FLNG) facilities, chemical and general industries requiring high-pressure and flow. These pumps were originally manufactured under the Marelli Bombas brand in Spain. The install base of Marelli pumps is over 10,000 units, many running for decades.